- Published: July 2016

- REF/ISBN: 9780852937976

- Edition: 1st

Publications in this series

Guidance on meeting expectations of EI Process safety management framework

- Element 1: Leadership, commitment and responsibility

- Element 2: Identification and compliance with legislation and industry standards

- Element 3: Employee selection, placement and competency, and health assurance

- Element 4: Workforce involvement

- Element 5: Communication with stakeholders

- Element 6: Hazard identification and risk assessment

- Element 7: Documentation, records and knowledge management

- Element 8: Operating manuals and procedures

- Element 9: Process and operational status monitoring, and handover

- Element 10: Management of operational interfaces

- Element 11: Standards and practices

- Element 12: Management of change and project management

- Element 13: Operational readiness and process start-up

- Element 14: Emergency preparedness

- Element 15: Inspection and maintenance

- Element 16: Management of safety critical devices

- Element 17: Work control, permit to work and task risk management

- Element 18: Contractor and supplier, selection and management

- Element 19: Incident reporting and investigation

- Element 20: Audit, assurance, management review and intervention

Foreword

Process safety management (PSM) is vital to ensuring safe and continued operations in major accident hazard (MAH) organisations. However, PSM is a multifaceted process, and a number of high profile incidents since 2005 have suggested that without a holistic understanding of the various factors required for effective PSM it can be difficult and inefficient to ensure, and measure, performance.

In 2010 the Energy Institute (EI) published High level framework for process safety management (PSM framework), which aimed to define what PSM should involve. Divided into four focus areas (process safety leadership, risk identification and assessment, risk management, and review and improvement) and sub-divided into 20 ‘elements’, it sets out a framework of activities MAH organisations should undertake to ensure PSM. Each element lists a number of high level activities organisations should meet (expectations).

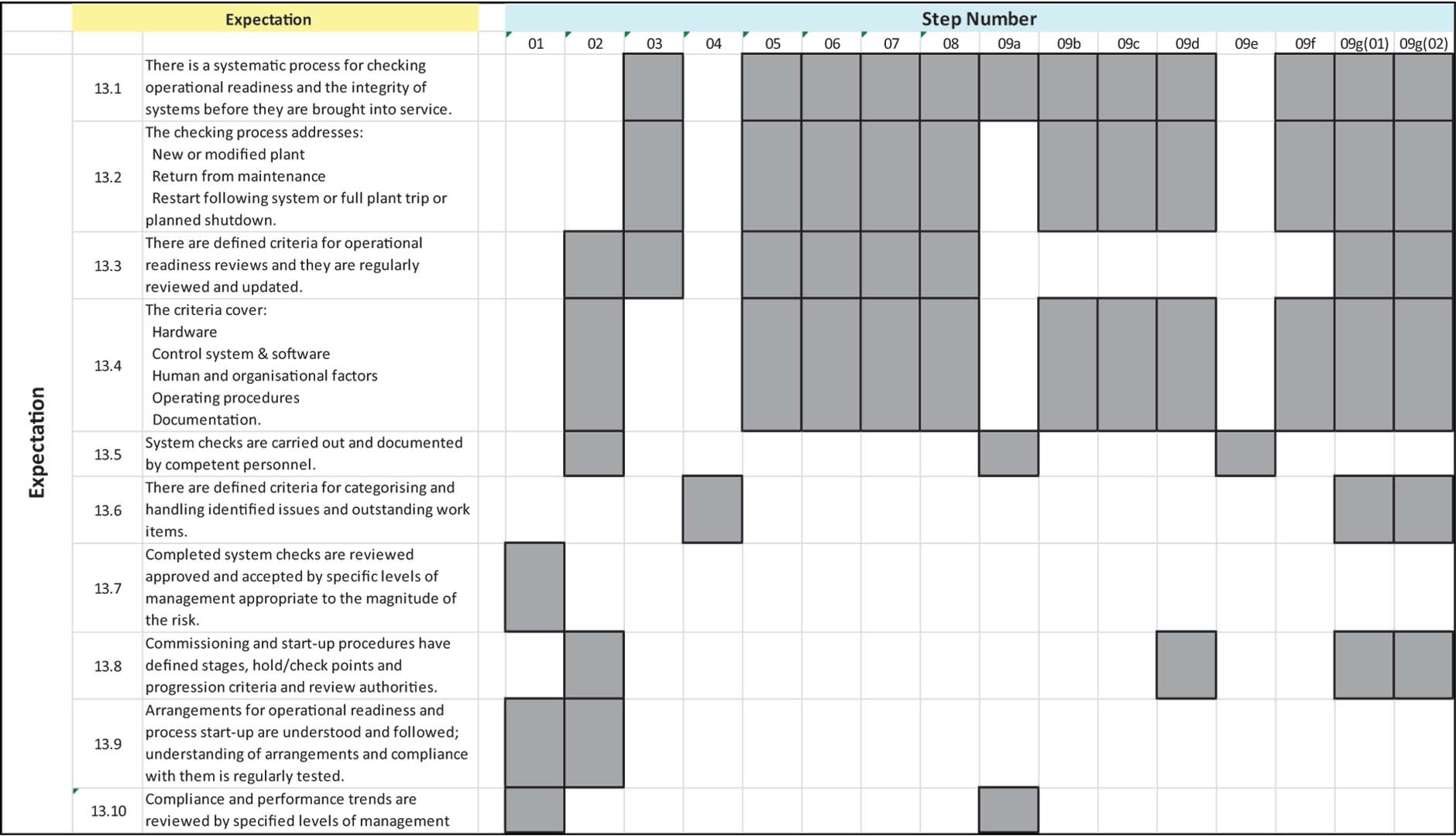

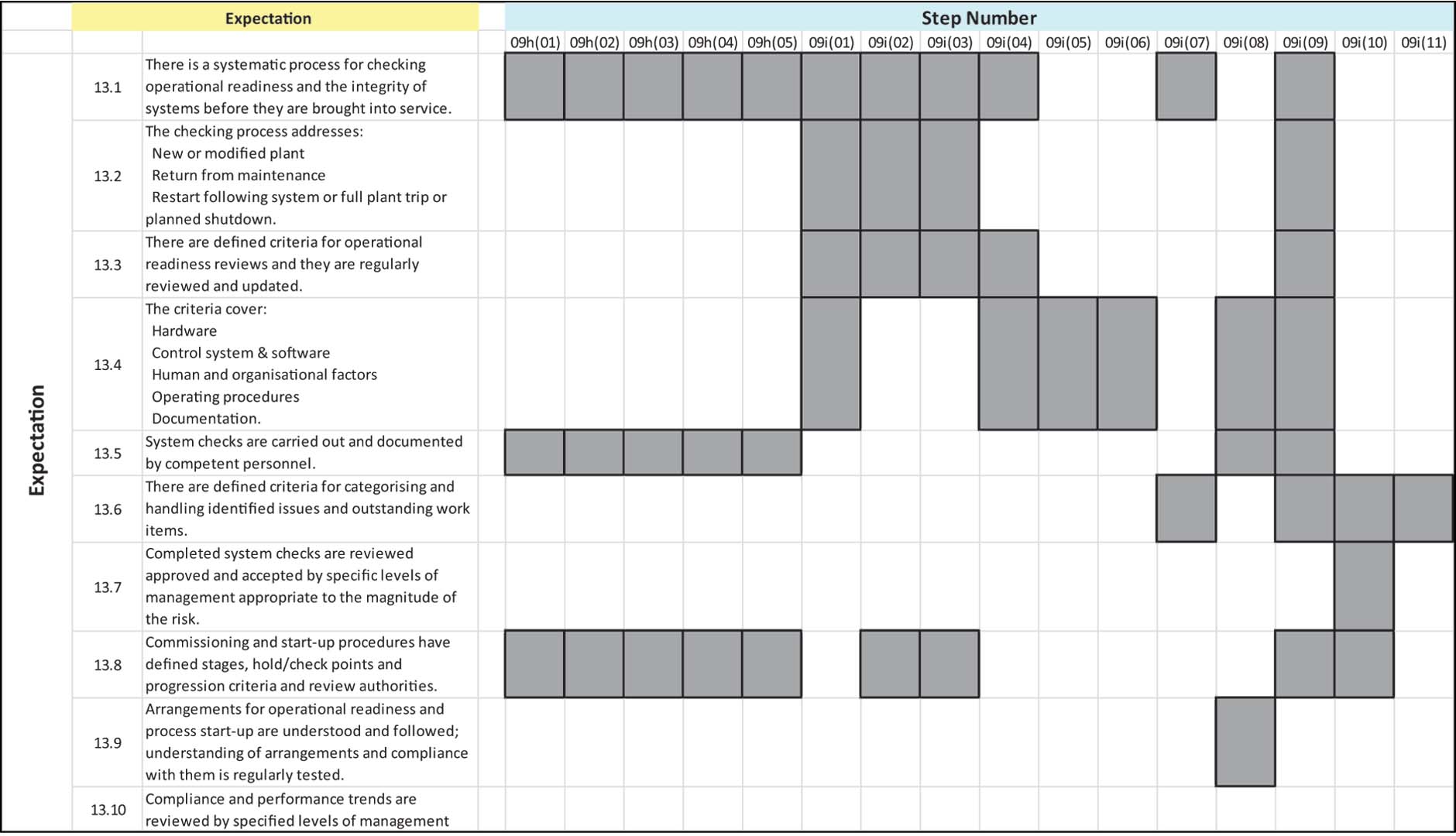

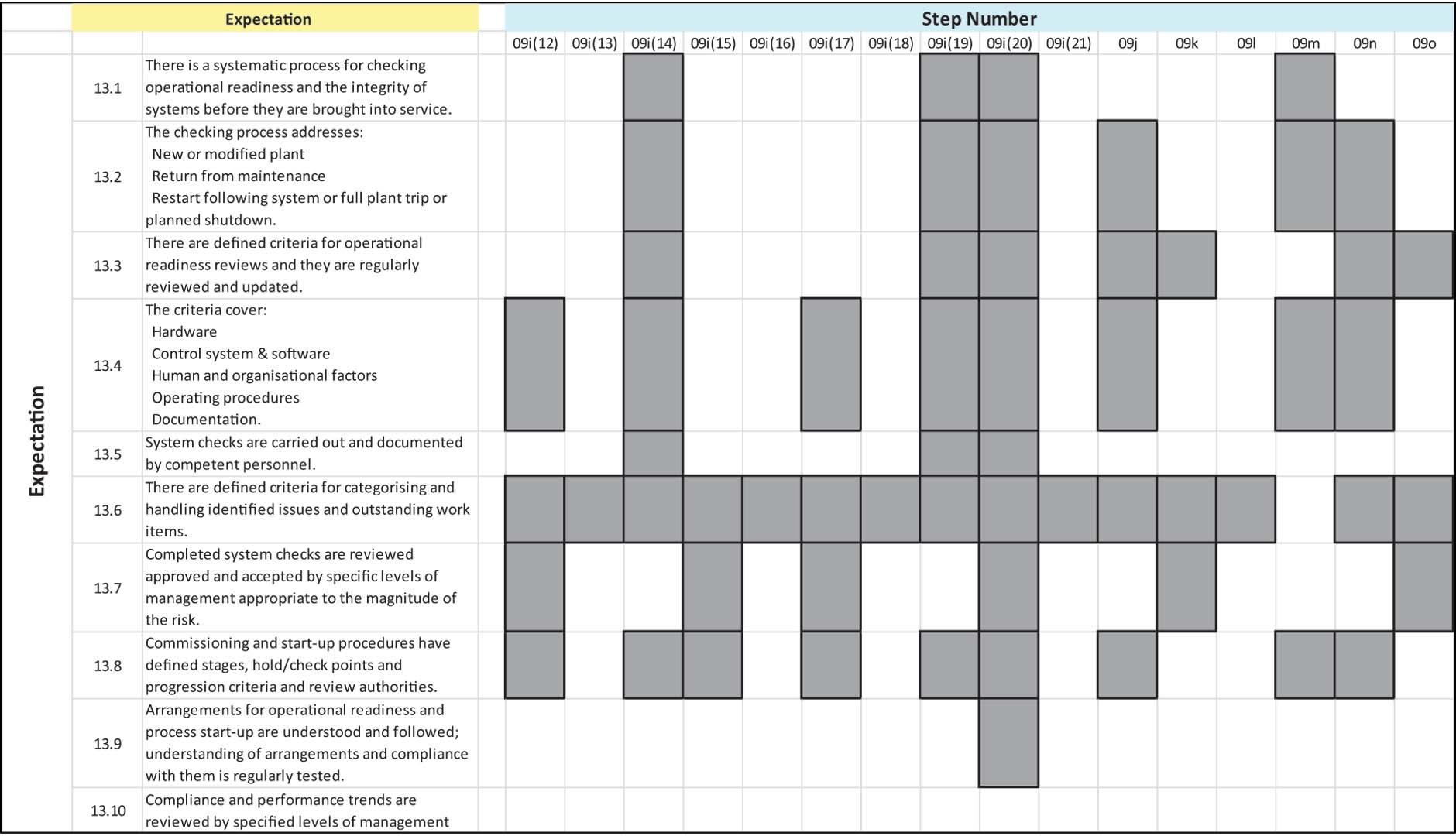

EI Guidance on meeting expectations of EI Process safety management framework is a series of 20 publications (guidelines) that build on the PSM framework. Commissioned by the EI Process Safety Committee (PSC) each guideline captures and presents current industry good practices and guidance on how organisations can meet the expectations set out in each element of the PSM framework. Each guideline includes:

- a logical flow diagram of activities (steps) the organisation should undertake to manage that element;

- descriptions of those steps;

- example performance measures (PMs) to measure the extent to which key steps have been undertaken;

- a list of further resources to help undertake key steps;

- a table mapping the steps against the expectations in the PSM framework, and

- annexes of useful information.

Readers implementing the guidance in this publication should be aware of the PSM framework and the other publications in this series, particularly if they are a manager with oversight of the wider implementation of PSM.

The information contained in this publication is provided for general information purposes only. Whilst the Energy Institute and the contributors have applied reasonable care in developing this publication, no representations or warranties, express or implied, are made by the Energy Institute or any of the contributors concerning the applicability, suitability, accuracy or completeness of the information contained herein and the Energy Institute and the contributors accept no responsibility whatsoever for the use of this information. Neither the Energy Institute nor any of the contributors shall be liable in any way for any liability, loss, cost or damage incurred as a result of the receipt or use of the information contained herein.

Suggested revisions are invited and should be submitted through the

Technical Department,

Energy Institute,

61 New Cavendish Street,

London, W1G 7AR.

1. Introduction

1.1 Operational readiness and process start-up

This guideline sets out good practices for operational readiness and plant start-up and the management of HS&E and process safety risks introduced into the business by commissioning and start-up of new plant or re-commissioning and start-up of existing plant. This guidance will address:

- start-up of new or modified plant and equipment;

- restart following partial or full plant trip or planned shutdown, and

- restart following return from maintenance.

The commissioning and start-up of new, modified or existing plant and equipment, if not appropriately managed, can significantly increase the levels of HS&E and process safety risk.

Management should ensure that risks arising from any form of start-up are systematically identified, assessed and managed and that there is a systematic process to verify that plant and equipment is in a safe condition, and that personnel are appropriately prepared, before start-up or return to normal operation.

1.2 Expectations for Element 13: Operational readiness and process start-up

Element 13 of EI High level framework for process safety management (‘PSM framework’) describes 10 expectations – arrangements and processes that organisations should (to an appropriate degree) have in place in order to ensure they are managing this aspect of PSM appropriately:

| ‘Overview | The commissioning and start-up of new, modified or existing plant and

equipment is a high risk operation. Management must ensure that there is a systematic process to verify that plant and equipment is in a safe condition, and that personnel are appropriately prepared, before start-up or return to normal operation. |

| 13.1 | There is a systematic process for checking operational readiness and the integrity of systems before they are brought into service. |

| 13.2 | The checking process addresses:

|

| 13.3 | There are defined criteria for operational readiness reviews and they are regularly reviewed and updated. |

| 13.4 | The criteria cover:

|

| 13.5 | System checks are carried out and documented by competent personnel. |

| 13.6 | There are defined criteria for categorising and handling identified issues and outstanding work items. |

| 13.7 | Completed system checks are reviewed, approved and accepted by specific levels of management appropriate to the magnitude of the risk. |

| 13.8 | Commissioning and start-up procedures have defined stages, hold/check points and progression criteria and review authorities. |

| 13.9 | Arrangements for operational readiness and process start-up are understood and followed; understanding of arrangements and compliance with them is regularly tested. |

| 13.10 | Compliance and performance trends are reviewed by specified levels of management.’ |

This guideline provides a process, along with guidance, to help organisations meet these expectations. It also suggests a number of compliance checks and performance measures (PMs) to measure the extent to which key activities involved in meeting these expectations have been or are being undertaken.

2. Arrangements for meeting expectations

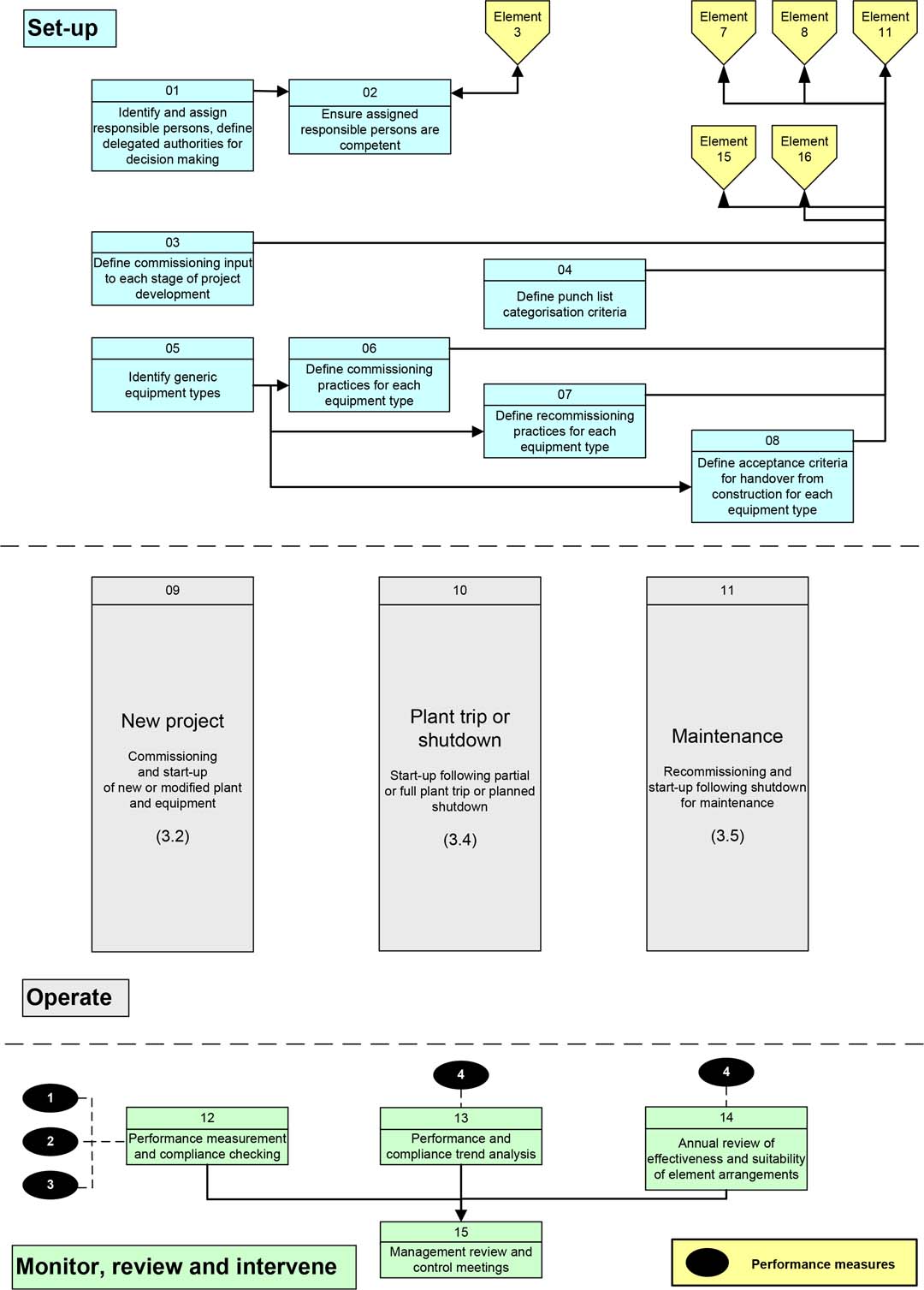

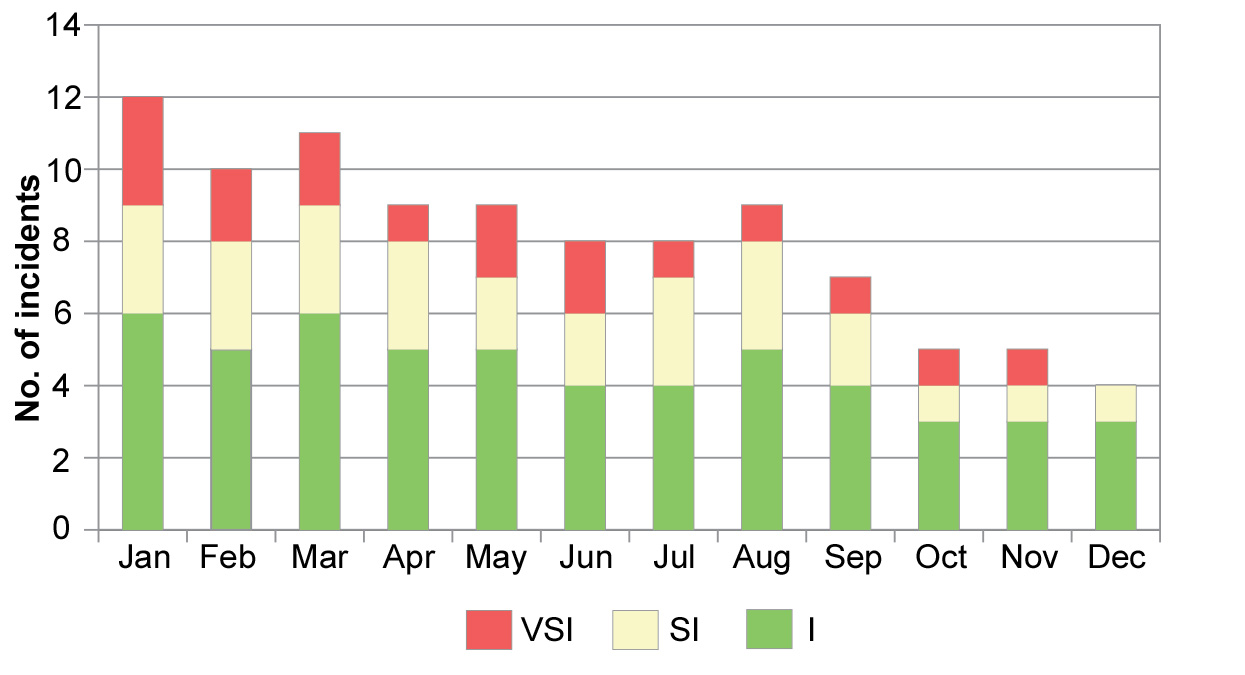

Figure 1 provides a logical flow diagram for the activities that should be in place to meet the expectations in element 13, to manage operational readiness and process start-up. It covers activities (steps) which should be undertaken by the organisation, across three phases: set-up (preparations to manage the element); operate (management of the element); and monitor, review and intervene (monitoring and reviewing the management of the element, and making appropriate interventions if the element is not being managed effectively).

The flow diagram provides an example of the logical arrangement of necessary activities. The reader should take cues from the arrangement and relationships between steps when determining the appropriate flow design for their own organisation. The flow diagram also shows interfaces with other elements, where this element may be dependent upon activities that are addressed by other elements – e.g. step 02 relies on there being an effective competence management system in place, as described in Guidance on meeting expectations of EI Process safety management framework element 3: Employee selection, placement and competency, and health assurance.

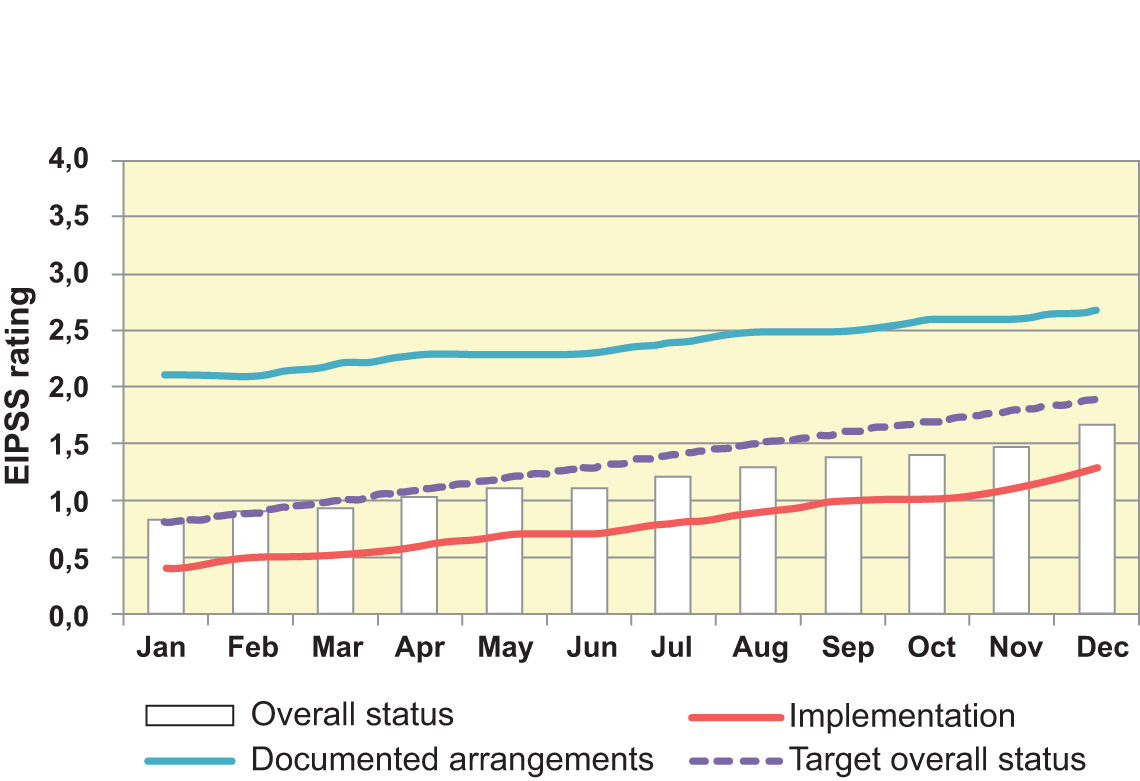

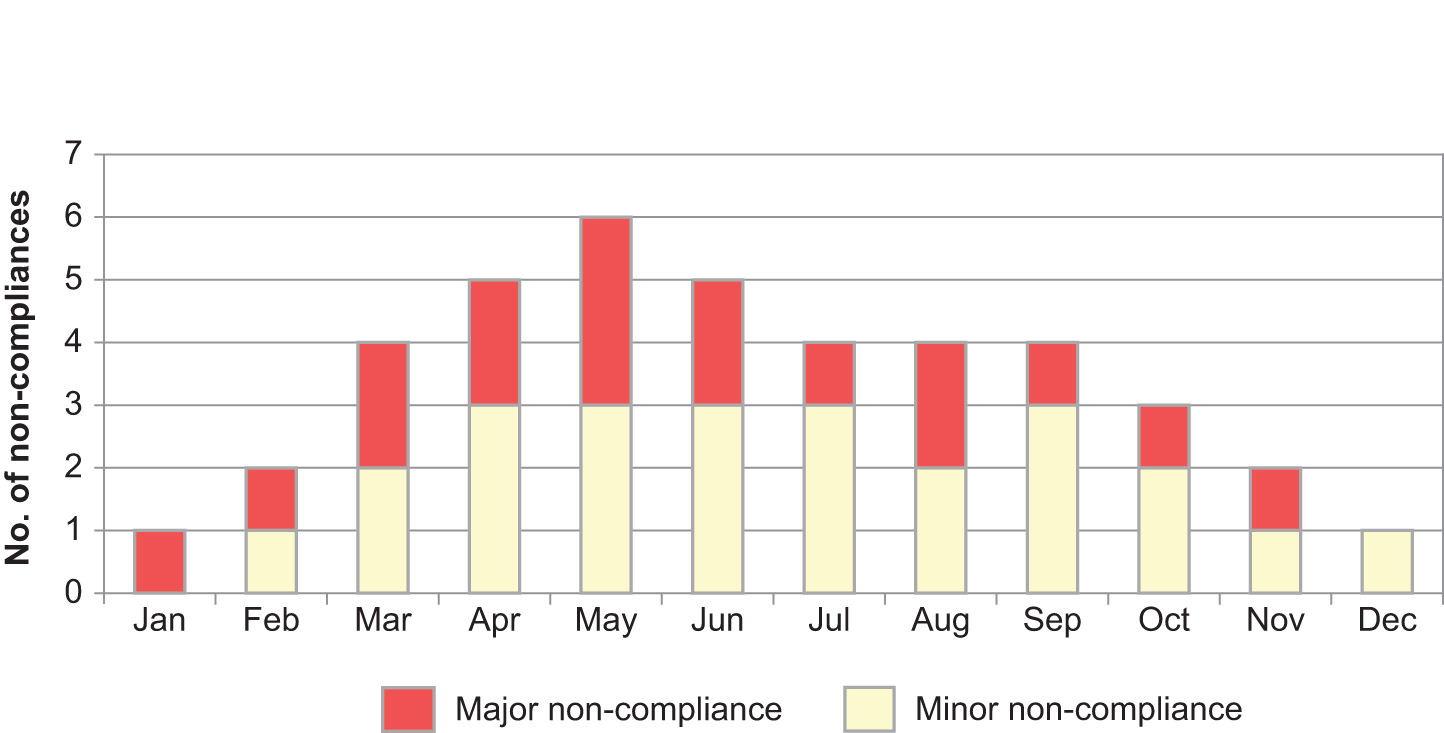

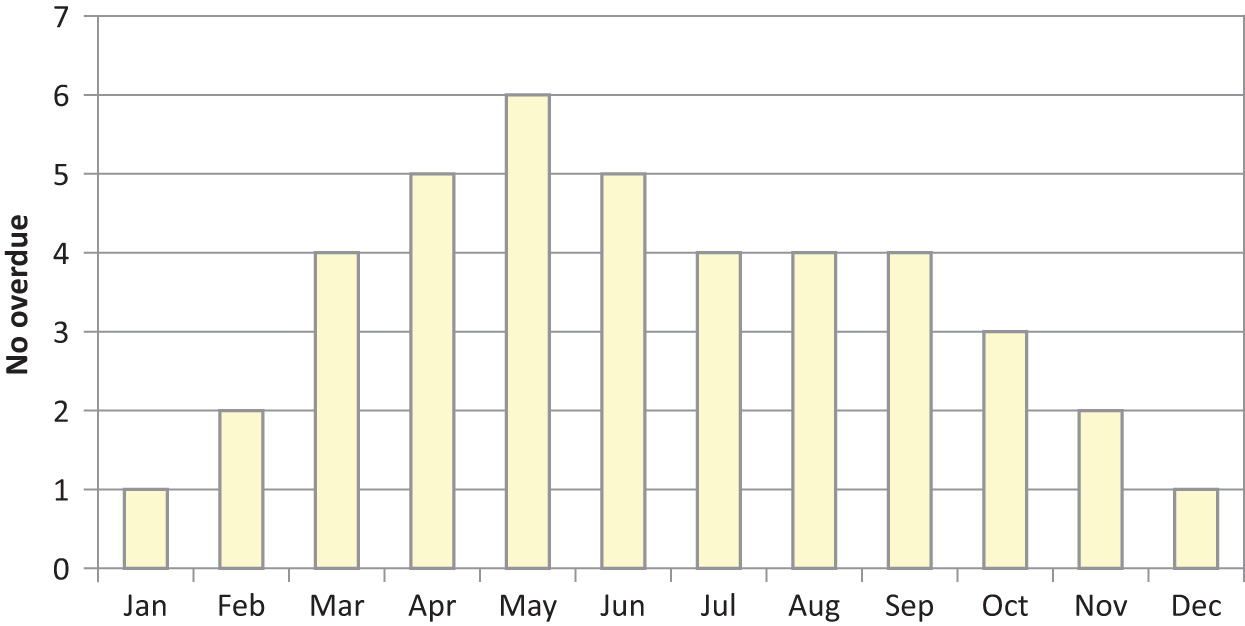

At specific points in the flow diagram process, PMs are suggested. These PMs are predominantly leading indicators designed to enable the measurement of the outputs from the element and the level of operational compliance with the expectations. Suggested PMs are described further in section 3.

2.1 provides guidance on the actions involved for each step, the deliverables that should result from those actions, the frequency at which the step should be undertaken. It also provides more detailed guidance notes.

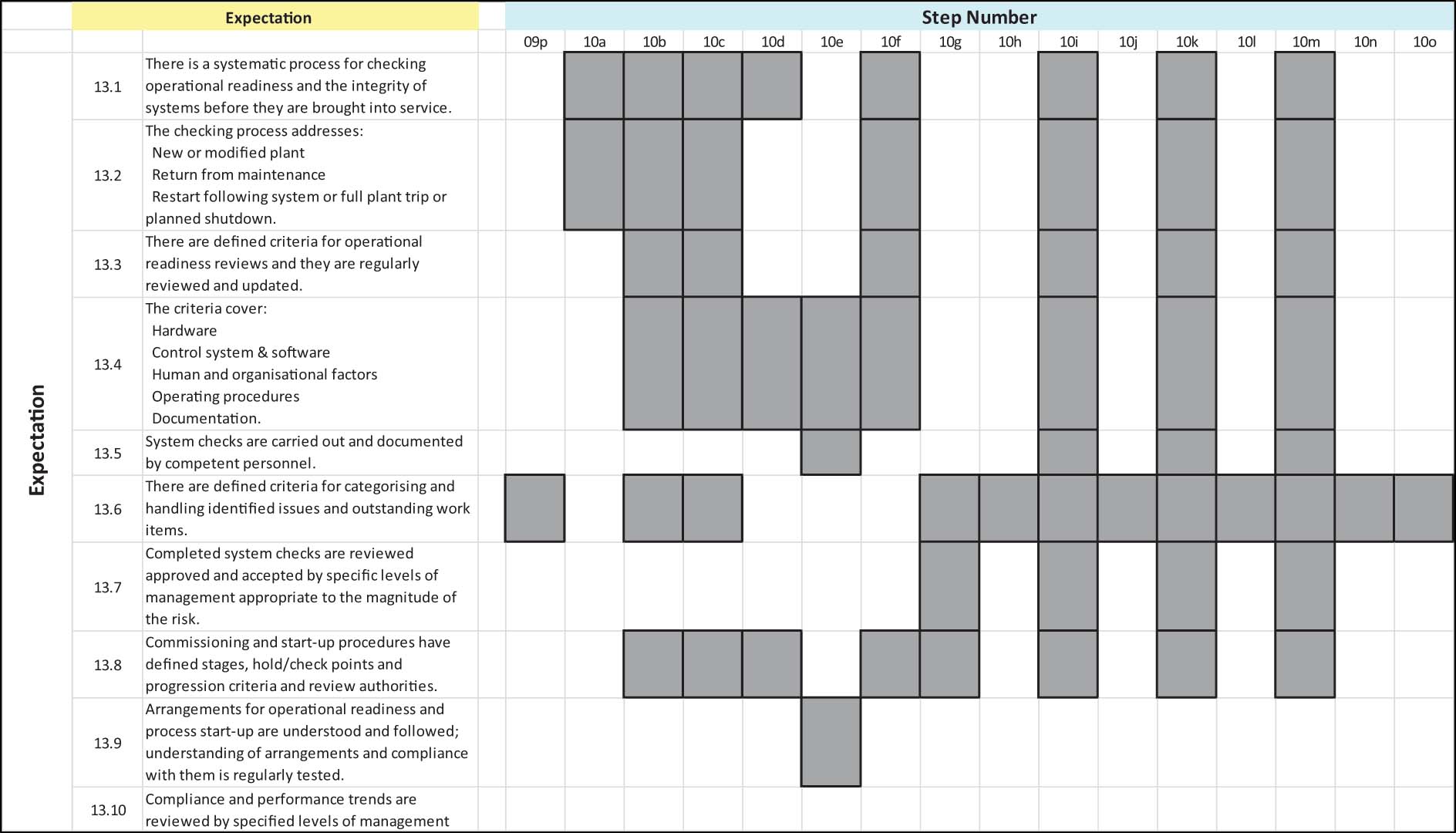

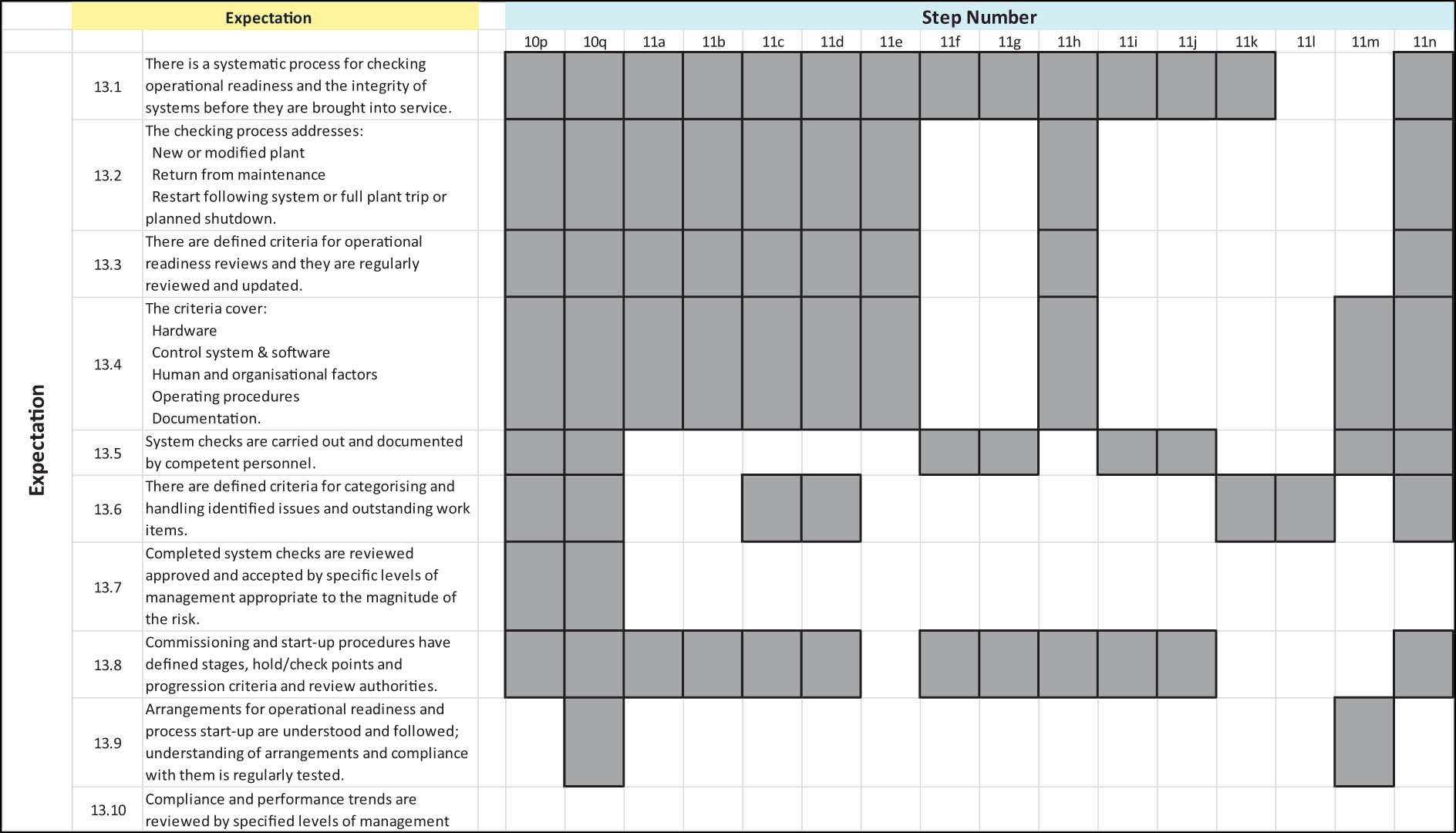

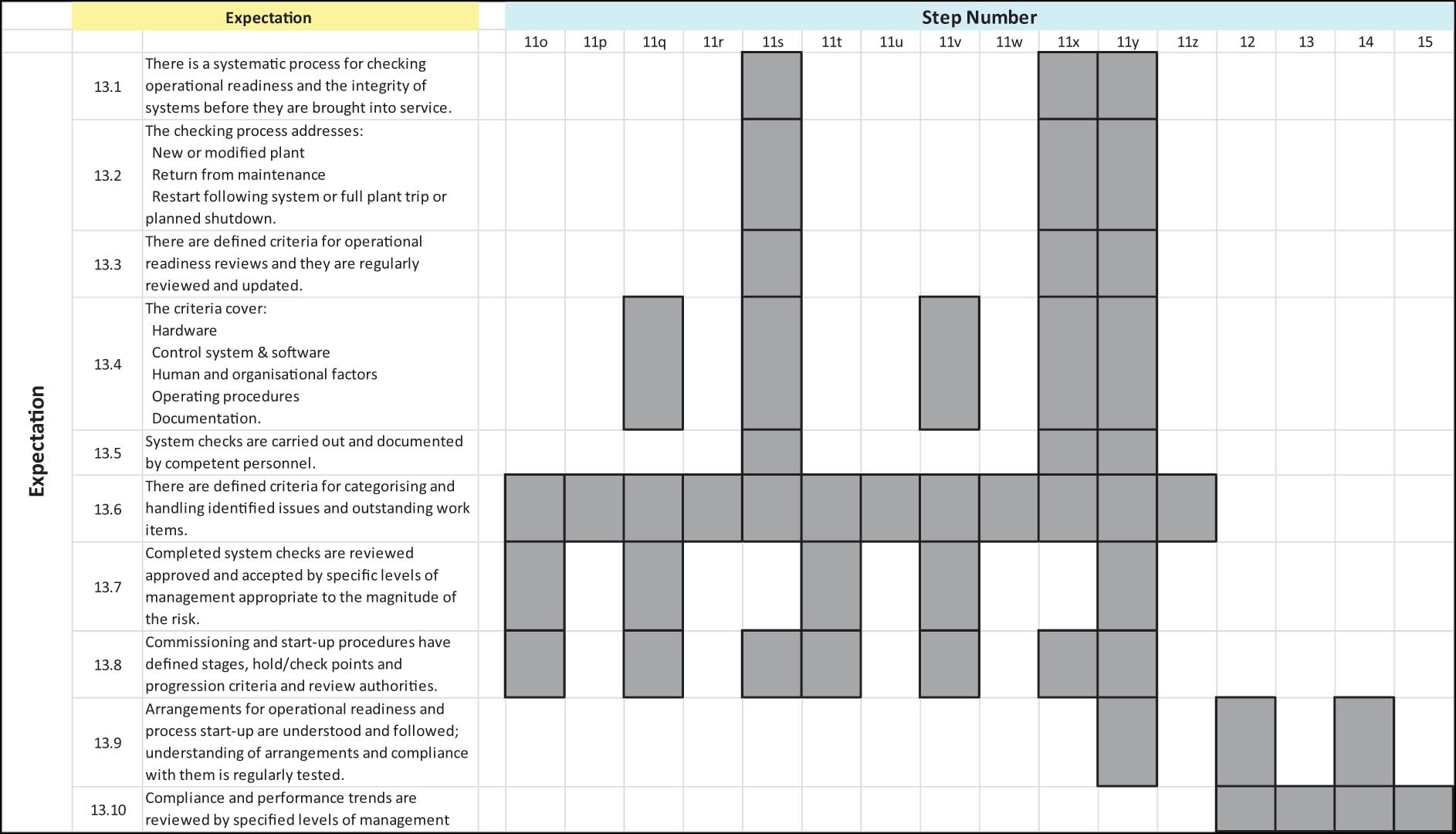

These steps have been mapped against element 13 expectations in Annex C. Note that although some expectations are fulfilled through several steps, and some steps help fulfil several expectations, all steps should be undertaken. As such, Annex C is for reference purposes only, to demonstrate that the arrangements outlined in this guideline enable the organisation to work towards fulfilling the requirements set out in element 13 of the PSM framework.

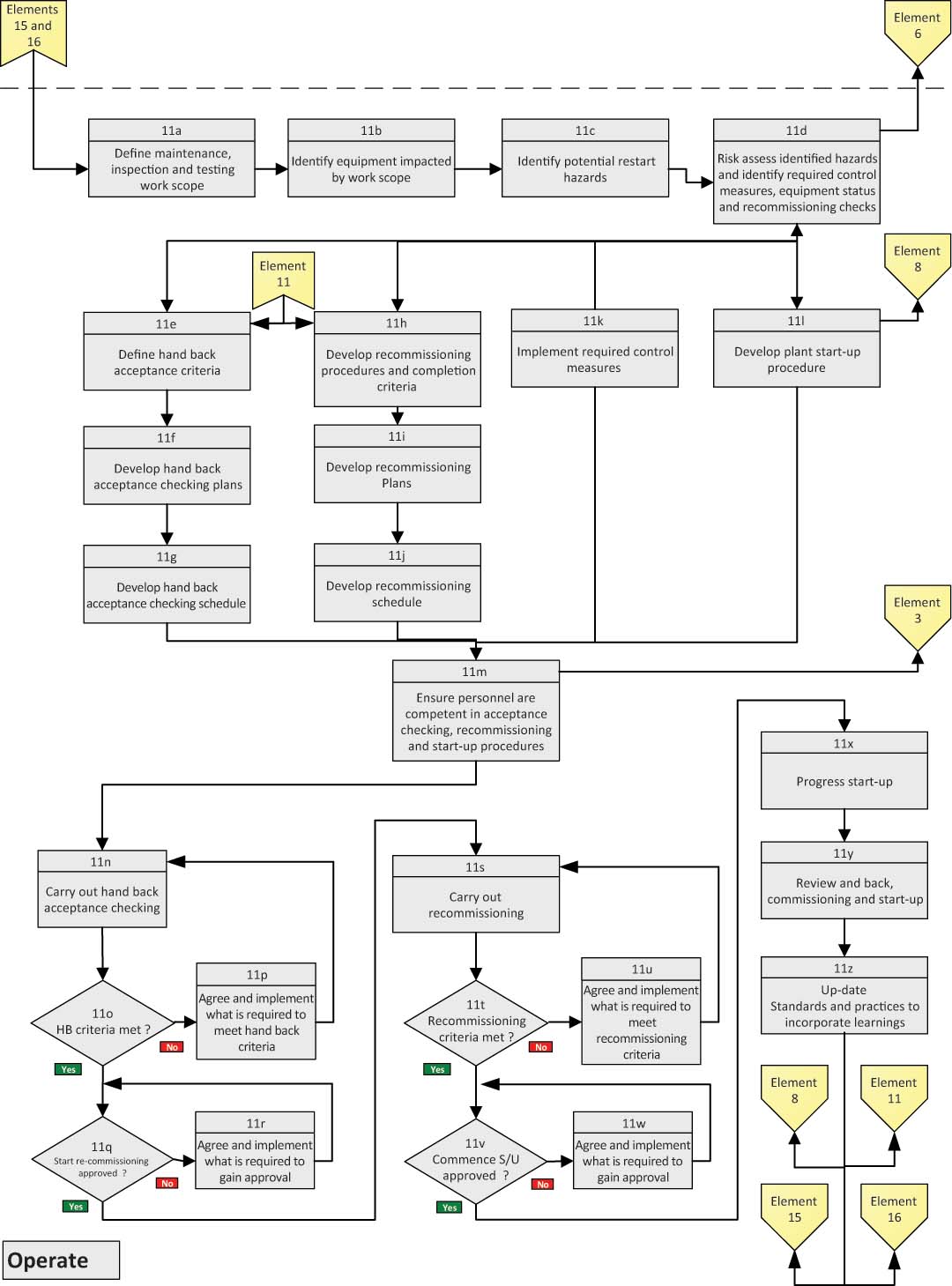

Figure 1: Logical flow diagram

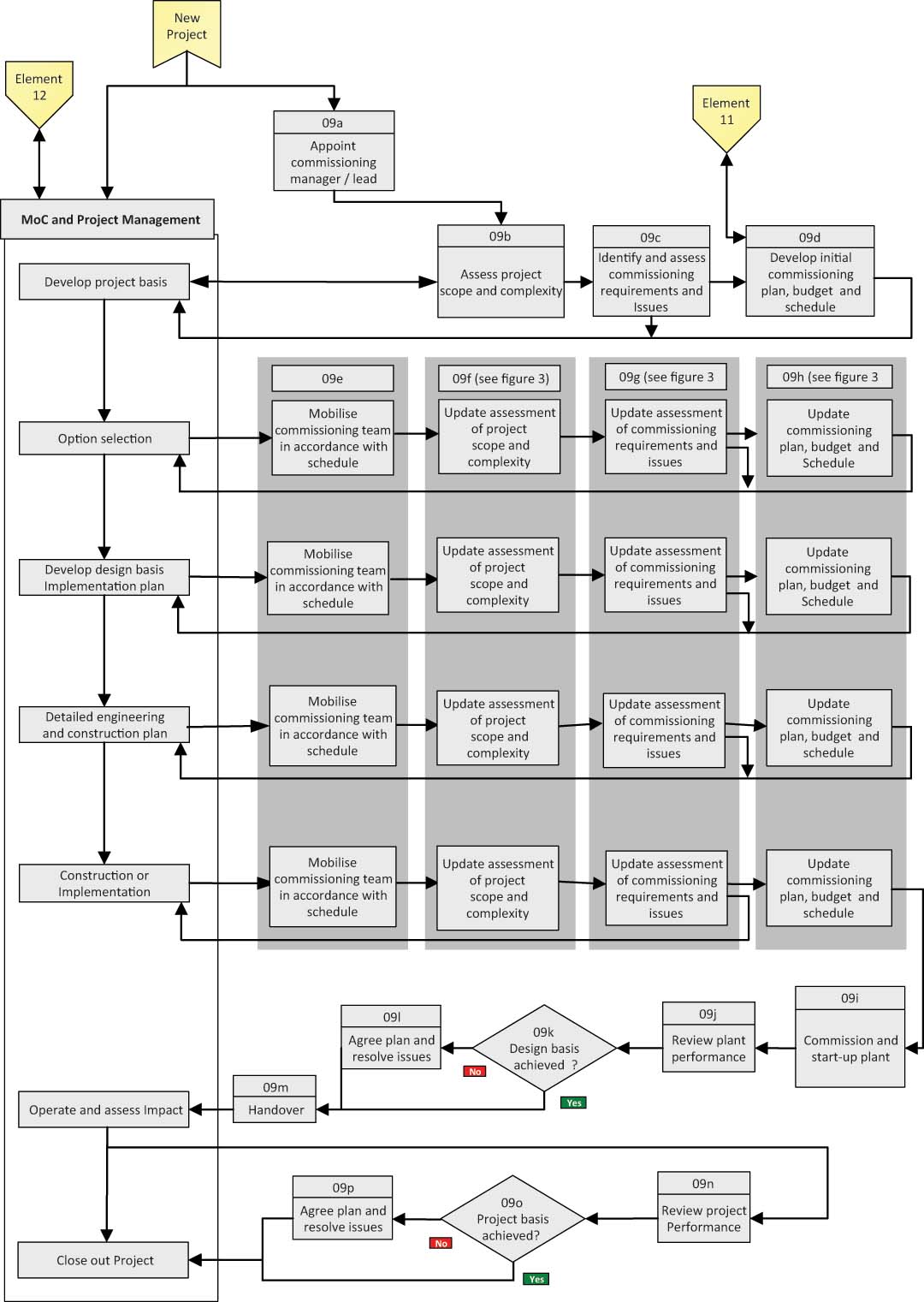

Figure 2: Commissioning and start-up of new projects – overview

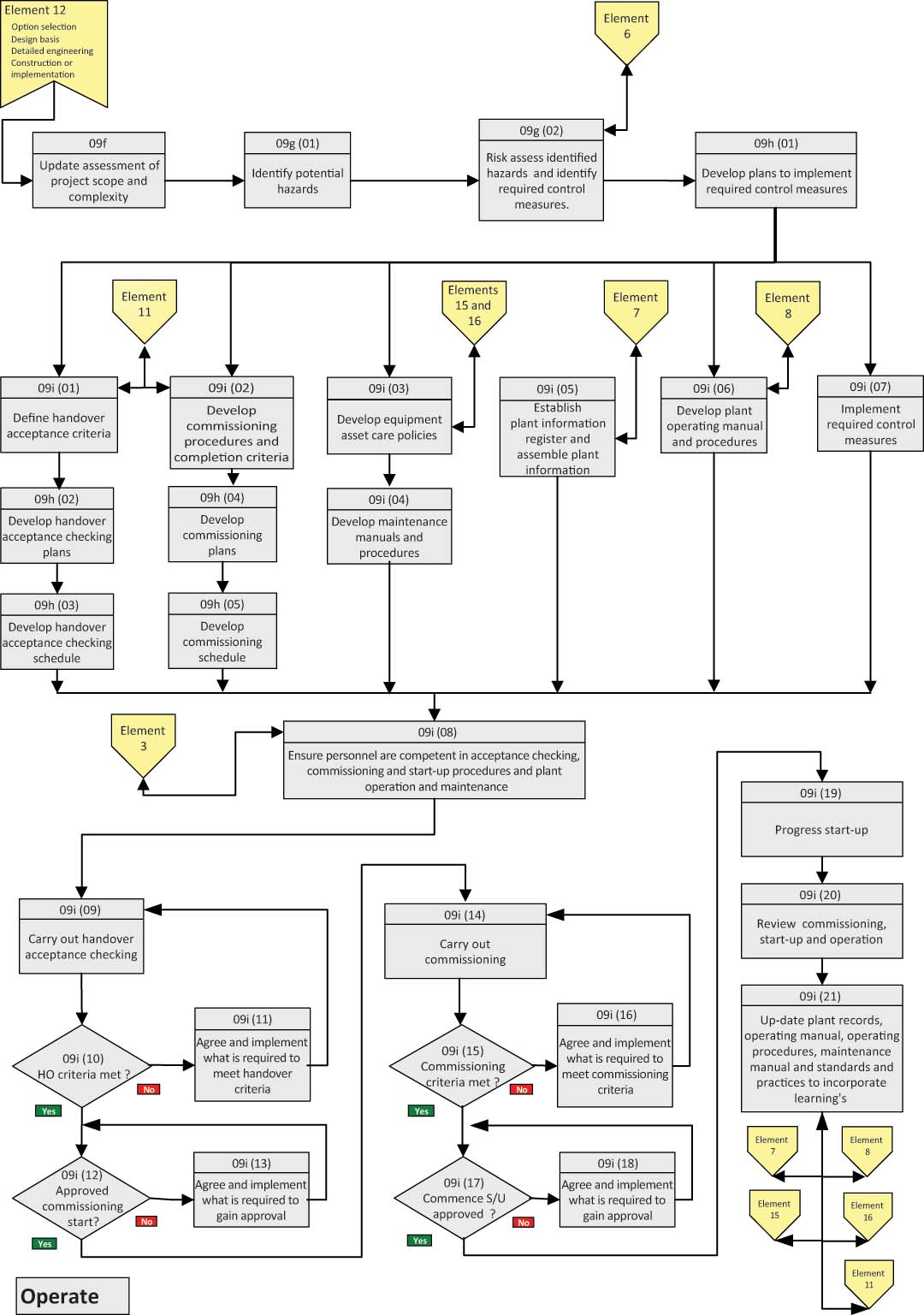

Figure 3: Commissioning and start-up of new projects – detail

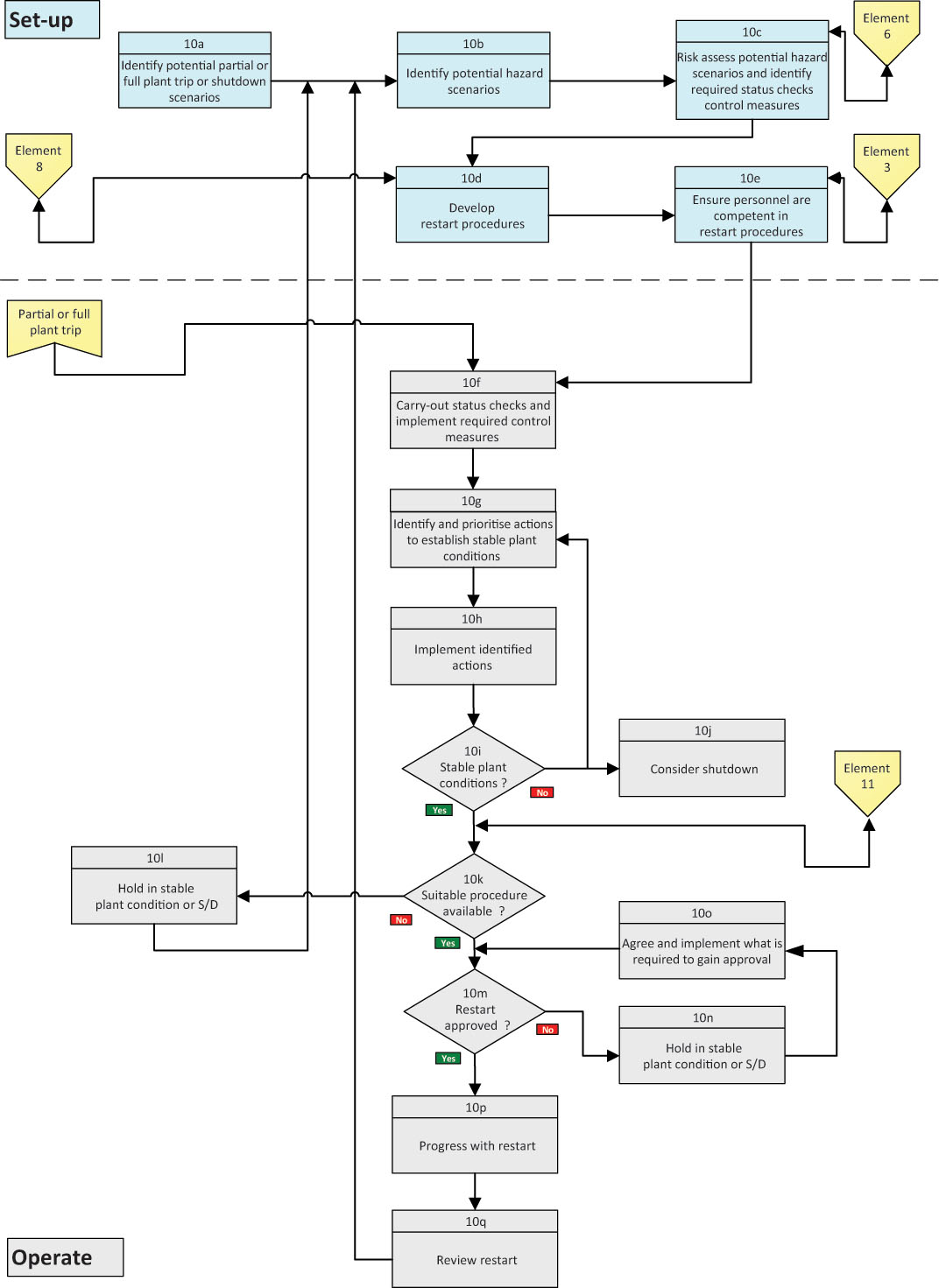

Figure 4: Restart after partial or full plant trip or shutdown

Figure 5: Restart after maintenance

2.1 Descriptions of actions for each step in the logical flow diagram

Actions

Identify and appoint responsible persons; define delegated authorities for decision making

Identify and appoint persons who will have defined roles and responsibilities for each aspect of the arrangements for leadership, commitment and responsibility.

Deliverables

Defined roles and responsibilities.

Agreed list of responsible persons who will:

- act as element owner, and

- carry out each aspect of the arrangements for the element.

Defined delegated authorities for decision making.

Agreed list of delegated authorities for each identified responsible person/position.

Frequency

During implementation then as required.

Guidance notes:

The senior accountable person, typically a director, business unit (BU) leader or site manager must ensure that accountabilities and responsibilities are assigned for each step in the process. Typically this can be achieved by appointing an element owner who will work with line managers to agree and assign these accountabilities and responsibilities

Typically, the element owner should be a senior line manager.

During the implementation phase the element owner will be required to coordinate the implementation of the element across the organisation, BU or site on behalf of the senior accountable person, working with other senior line managers to ensure that the implementation is appropriately planned and resourced and that any issues are resolved.

The element owner should also ensure that delegated authorities for decision making within the element are defined and approved.

Following implementation, during the operational phase the element owner should work with the other senior line managers to ensure that the element continues to operate as intended. In effect the element owner should act as a coach to the management team, building their understanding and confidence in the use of the element.

Actions

Ensure competence of appointed responsible persons

Deliverables

Training material.

Competency assessment.

Training schedule.

Competent persons.

Frequency

During implementation then as required.

Guidance notes:

The element owner should ensure that the required competencies are defined and agreed for all persons with assigned roles and responsibilities within the element and that each of these people is trained and coached appropriately to develop these required competencies.

They should also ensure that training and development programmes and routine personnel performance appraisals take into account these required competencies. This should be accomplished by means of Guidance on meeting expectations of EI Process safety management framework Element 3: Employee selection, placement and competency, and health assurance.

Actions

Define commissioning input to each stage of project development

Deliverables

Agreed definition of the commissioning and startup issues which will be considered in each stage of the project development process of a project.

Required commissioning team input to, and participation in and project development process gate reviews.

Frequency

During implementation then updated as required (review for each project).

Guidance notes:

The arrangements for operational readiness and process start-up, as they relate to new projects, need to operate in conjunction with the arrangements for Guidance on meeting expectations of EI process safety management framework Element 12: Management of change and project management. This will ensure that commissioning and start-up are appropriately considered throughout the development of a project.

The element owner should work with the element 12 owner to ensure that there is a coordinated approach to the arrangements for both elements which ensures that commissioning and start-up are appropriately considered throughout the development of a project.

The element owner should ensure that the required input from the commissioning and start-up team at each project development stage is clearly defined. This should cover issues such as:

- early nomination of a commissioning lead/manager;

- defining the commissioning scope;

- development of a commissioning budget;

- commissioning plan;

- commissioning schedule;

- operability review;

- maintainability review;

- interface / handover procedures with project construction and operations/owner teams;

- authorities for decision making, and

- the attendance and role of commissioning team in review meetings

Actions

Define punch list categorisation criteria

Deliverables

Agreed categories for punch list (outstanding work) items and criteria for categorisation of the identified items.

Frequency

During implementation then updated as required (review for each project).

Guidance notes:

The element owner should ensure that agreed categories are defined for 'punch list' (outstanding work) items that are identified during the checking of completion status. These completion status checks will typically be carried out at stages of a project’s development and at specific stages of the maintenance work flow:

- completion of project construction prior to handover for commissioning;

- completion of project commissioning prior to start-up;

- completion of maintenance work prior to handback for re-commissioning, and

- completion of plant re-commissioning prior to start-up.

Typically 'punch list' (outstanding work) items are assigned one of the following categories:

- Must be completed before handover for commissioning or recommissioning can be approved.

- Must be completed before project start-up or plant restart can be approved.

- Can be completed after plant start-up. Typically items assigned to this category will have a nominated responsible person and an agreed completion date identified.

The element owner should also ensure that clear criteria are defined to provide a consistent guide to decision making when deciding which category an outstanding work item will be assigned to.

Actions

Identify generic equipment types used within the organisation

Define commissioning and recommissioning practices for each identified equipment type

Define acceptance criteria and checks for handover from construction for each identified equipment type

Deliverables

Listing of generic equipment types used within the organisation.

Defined commissioning practices for each identified equipment type.

Defined recommissioning practices for each identified equipment type.

Defined acceptance criteria and checks for handover from construction for each identified equipment type.

Frequency

During implementation then updated as required (review for each project).

Guidance notes:

In order to assure that there is a consistent approach to handover for commissioning or re-commissioning and start-up together with the execution of commissioning and recommissioning, the following should be clearly defined:

- acceptance criteria for handover from construction or maintenance;

- safe working practices for commissioning and re-commissioning, and

- acceptance criteria for handover for project start-up or plant restart.

These acceptance criteria and safe working practices should be defined in accordance with Guidance on meeting expectations of EI process safety management framework Element 11: Standards and practices.

The element owner should ensure that the organisation decides whether the definition of these acceptance criteria and safe working practices will be done as a stand-alone activity or as something which is gradually developed and enhanced with each new project and maintenance activity. In either case the element owner should retain accountability for ensuring that suitable acceptance criteria and safe working practices are developed and are available to support each project and maintenance activity.

Actions

Appoint commissioning manager/lead

Deliverables

Nominated individual appointed with required competence and accountability for:

- safe, in-full, on schedule and on budget commissioning and startup of the project;

- required commissioning and start-up input to all stages of project development;

- establishing and updating the commissioning and start-up plan, schedule and budget, and

- establishing and maintaining the required commissioning and startup team.

Frequency

As required by schedule.

Guidance notes:

At the earliest stages of the development of a project a manager should be appointed who will have accountability for:

- safe, in-full, on schedule and on budget commissioning and start-up of the project;

- required commissioning and start-up input to all stages of project development;

- establishing and updating the commissioning and start-up plan, schedule and budget, and

- establishing and maintaining the required commissioning and start-up team.

This commissioning manager or commissioning lead should be appointed during the development of the project basis. They will typically manage the interface between project construction group and the groups which will ultimately operate and maintain the facilities provided by the project.

The commissioning manager/lead should ensure that the facilities provided by the project are ultimately handed over to groups who are ready, willing and able to operate, maintain and support them.

This role is often overlooked for smaller projects and this is demonstrably a major mistake. Without a defined accountability for commissioning and start-up, important activities will be overlooked. Examples are:

- out of date plant operating manuals, plant drawings and records which have not been updated to incorporate modifications made by small projects;

- inconsistent equipment types which add to the complexity of operation and maintenance;

- inadequate spares holdings;

- inadequate support contracts, and

- Inadequate training of personnel expected to operate and maintain the new facilities.

Actions

Assess project scope and complexity

Identify and assess commissioning requirements and issues

Develop initial commissioning plan, budget and schedule

Deliverables

Agreed initial assessment of project scope and complexity

Agreed initial assessment of commissioning requirements and issues, taking into account needs arising from:

- major rotating equipment;

- major/complex control and ESD systems;

- furnaces and boilers;

- exotic material;

- high pressure system;

- vendor fabricated skid mounted or packaged systems, and

- off-site fabricated module assemblies.

Agreed initial assessment of required commissioning and start-up team for each stage of the project.

Agreed initial commissioning start-up plan.

Agreed initial commissioning and start-up schedule.

Agreed initial commissioning and start-up budget.

Frequency

As required by schedule.

Guidance notes:

At the project basis stage the appointed commissioning manager/lead should ensure that issues of commissioning, start-up, operability and maintainability are taken into account. Importantly, they should ensure that at this earliest stage of project development and evaluation there is appropriate recognition of the commissioning requirements and that the project schedule and budget make appropriate provision for the necessary commissioning and start-up activities.

The appointed commissioning manager/lead should ensure that there is an initial assessment of the scope and complexity of the project and that there is an initial assessment of the commissioning requirements and issues, taking into account needs arising from:

- major rotating equipment;

- major/complex control and ESD systems;

- furnaces and boilers;

- exotic material;

- high pressure system;

- vendor fabricated skid mounted or packaged systems, and

- off-site fabricated module assemblies.

The appointed commissioning manager/lead should also ensure that there is an initial assessment of the required commissioning and start-up team for each stage of the project and that an outline commissioning and start-up plan, schedule and budget are developed and included in the project basis.

It should be recognised that at this early stage the level of definition of the project may be very low and that this assessment will need to be updated as the project development progresses and the level of definition increases.

Actions

Mobilise commissioning team in accordance with agreed plan and schedule

Deliverables

Commissioning and startup team mobilised for each stage of the project in accordance with the appropriate update of the agreed commissioning and start-up plan and schedule.

Frequency

As required by schedule.

Guidance notes:

The commissioning and start-up team should be mobilised for each stage of the project’s development in accordance with the appropriate update of the agreed commissioning plan, schedule and budget.

Actions

Update assessment of project scope and complexity at each stage of project development

Deliverables

Agreed updated assessment of project scope and complexity at each stage of the project’s development:

- project basis;

- option selection;

- design basis;

- detailed engineering, and

- construction/ implementation.

Frequency

As required by schedule.

Guidance notes:

The commissioning manager should ensure that, at each stage of the project’s development the assessment of the project scope and complexity is reviewed and updated to take account of the increasing levels of definition of the project.

Guidance notes:

The commissioning manager should ensure that, at each stage of the project’s development the commissioning requirements and issues is reviewed and updated to take account of the increasing levels of definition of the project.

Guidance notes:

The commissioning manager should ensure that, at each stage of the project’s development the overall commissioning and start-up plan is reviewed and updated to take account of the increasing levels of definition of the project.

Actions

Identify potential hazards

Risk assess identified hazards and identify required control measures

Develop plans to implement required control measures

Deliverables

Agreed update of:

- identified potential commissioning and startup hazards;

- risk assessments of identified potential commissioning and startup hazards.

- required control measures

- plans and schedules to implement required control measures at each stage of the project’s development;

- project basis;

- option selection;

- design basis;

- detailed engineering, and

- construction/ implementation.

Frequency

As required by schedule.

Guidance notes:

The commissioning manager should ensure that, at each stage of the project’s development as the level of definition increases, a review is carried out to identify potential hazards arising from commissioning and start-up. These identified hazards should be risk assessed and the required control measures identified. The hierarchy of control should be applied when selecting the risk control measure:

- elimination;

- reduction;

- interception;

- control;

- personal protective equipment (PPE);

- discipline (making sure that all controls are monitored, reviewed and enforced), and

- emergency response.

The 'hierarchy of control' is consistent with the philosophy of intrinsically safe design in that the first control measure that should be considered is that of making appropriate modifications to the facility or the procedure to eliminate the source of the hazard.

The commissioning manager should ensure that appropriate feasible plans and schedules should be developed for the implementation of the agreed required control measures.

The hazard identification and risk assessment for the commissioning and start-up may be incorporated into the risk assessments carried out as part of each stage of the project’s development as defined in Guidance on meeting Expectations of EI process safety management framework Element 12: Management of change and project management. Alternatively the commissioning manager may decide to run this as a separate activity alongside and with reference to the risk assessments being carried out by the project team.

The completed risk assessments should be reviewed and approved by an appropriate line manager with the necessary competency and delegated level of authority.

Actions

Define and agree handover criteria for handover from construction

Develop handover acceptance checking plans

Develop handover acceptance checking schedule

Deliverables

Agreed acceptance criteria for handover of equipment from construction to commissioning and start-up team.

Agreed handover acceptance checking plans and schedule, updated at each stage of the project’s development, setting out:

- how acceptance checking will be carried out;

- where acceptance checking will be carried out;

- who will carry out the acceptance checking.

- who will have authority to accept handover of equipment to the commissioning and startup team, and

- when acceptance checking will be carried out.

Frequency

As required by schedule.

Guidance notes:

Criteria for accepting handover of plant systems and equipment should be agreed between the project/construction team and the commissioning team. These should take account of predefined criteria as defined in step 08. These may need to be updated as the level of definition increases as the project development progresses.

A plan and schedule should be developed for the handover acceptance checking and this should be updated at each stage of the project’s development. Plans and schedules should be developed for each system and they should be developed in conjunction with the construction schedule. The appropriate integration and optimisation of these plans and schedules may provide opportunities to shorten the overall schedule and advance the date when the project is brought online, with the consequent earlier delivery of the targeted business benefits.

Actions

Develop commissioning procedures and completion criteria

Develop commissioning plans

Develop commissioning schedule

Deliverables

Agreed commissioning procedures with agreed criteria for progression from commissioning to start-up.

Agreed commissioning plans and schedule, updated at each stage of the project’s development, setting out:

- how commissioning will be carried out;

- where commissioning will be carried out;

- the resource required and who will carry out the commissioning;

- who will have authority to approve progression from commissioning to start-up, and

- when commissioning will be carried out.

Frequency

As required by schedule.

Guidance notes:

Commissioning procedures should be developed and criteria for progressing from commissioning to start-up should be approved by the commissioning manager. These should take account of predefined commissioning safe working practices as defined in step 06 and any predefined acceptance criteria as defined in step 08. These may need to be updated as the level of definition increases as the project development progresses.

A plan and schedule should be developed for the commissioning and this should be updated at each stage of the project’s development. Plans and schedules should be developed for each system and they should be developed in conjunction with the construction schedule and handover acceptance checking schedule. The appropriate integration and optimisation of these plans and schedules may provide opportunities to shorten the overall schedule and advance the date when the project is brought online, with the consequent earlier delivery of the targeted business benefits.

Actions

Develop plant and equipment asset care policies

Risk based inspection, testing and maintenance requirements

This should be reviewed and approved by persons with the delegated authority to do so

Deliverables

Asset care policies in accordance with Guidance on meeting expectations of EI process safety management framework Element 15: Inspection and maintenance and Guidance on meeting expectations of EI process safety management framework Element 16: Management of safety critical devices.

Identified:

- legislative requirements;

- requirements from company and industry standards;

- degradation mechanisms;

- consequence of failure

- unmitigated risk;

- proposed interventions, and

- managed risk.

Justified inspection and preventative maintenance interventions for each item of plant and equipment.

'Identified run basis' or 'normal operating envelope' for each item of plant and equipment (within which the asset care policy remains valid).

Frequency

As required by schedule then updated as required.

Actions

Develop inspection, testing and maintenance manuals and procedures

This should be reviewed and approved by persons with the delegated authority to do so

Deliverables

Approved inspection, testing and maintenance manuals and procedures, in accordance with Guidance on meeting expectations of EI process safety management framework Element 15: Inspection and maintenance and Guidance on meeting expectations of EI process safety management framework Element 16: Management of safety critical devices setting out:

- what should be done;

- how it should be done;

- the reasons each item is required to be done, and

- special tooling or equipment requirements.

Frequency

As required by schedule then updated as required.

Guidance notes:

The commissioning manager should ensure that the new plant and equipment should be added to the asset register. They should also ensure that the testing, inspection and maintenance requirements are defined for the new plant and equipment. These should ideally be in the form of asset care policies which identify degradation mechanisms, consequence of failure and expected degradation rates. Risk based testing, inspection and maintenance requirements should be identified in accordance with element 15 and element 16.

These asset care policies should be developed using risk management principles to define the appropriate care approach and specific testing, inspection and maintenance interventions or control measures, necessary to deliver the required level of performance/reliability from the new plant and equipment (tolerable level of risk).

It is likely that in many cases a 'generic asset care policy' will cover a number of identical or similar identified assets. In these cases the team developing the asset care policies will need to consider both the type of equipment and the operating environment when deciding whether it is appropriate to develop a generic asset care policy to cover a 'class' of assets or items of work equipment.

In addition to generating asset care policies for the new plant and equipment, the impact of the project on existing plant and equipment should be considered and where necessary asset care policies for existing assets should be updated to take into account any changes to service or operating conditions caused by the project.

The commissioning manager should also ensure that the necessary testing, inspection and maintenance manuals are developed for the new plant and equipment in accordance with element 15 and element 16.

When a procedure or work pack is developed for inspection and maintenance it will assemble or reference many different sources of information. In some cases this information may have to be developed from basics. The procedures and work packs should comply with the guidelines defined in element 15 and element 16.

In many cases a work activity may be repeated in the future, so it is important that the procedures or work packs are reused wherever possible in order to assure a consistent approach and to achieve maximum efficiency and effectiveness from the available technical and planning resource.

Actions

Establish plant information register and assemble plant information

This should be reviewed and approved by persons with the delegated authority to do so.

Deliverables

The required records and information, in accordance with Guidance on meeting expectations of EI Process safety management framework element 7: Documentation, records and knowledge management to manage HS&E and process safety risk and support safe operation.

Frequency

As required by schedule then updated to incorporate any changes.

Guidance notes:

As the project progresses through the development stages and on into commissioning, start-up and operation, the commissioning manager should ensure that a plant information register is established and the necessary plant information assembled. This should be done in accordance with Guidance on meeting expectations of EI process safety management framework Element 7: Documentation, records and knowledge management. The assembled plant information should be sufficient to manage HS&E and process safety risk and support the safe operation and maintenance of the new plant and equipment.

Actions

Develop plant operating manual and procedures

This should be reviewed and approved by persons with the delegated authority to do so.

Deliverables

Approved plant operating manual and procedures, in accordance with Guidance on meeting expectations of EI Process safety management framework element 8: Operating manuals and procedures. Setting out the necessary information and procedures to support:

- safe start-up;

- safe operation;

- actions to be taken in event of excursions beyond defined operating limits;

- actions to be taken in response to alarm or trip conditions;

- safe shutdown, and

- training of personnel.

Frequency

As required by schedule then updated to incorporate any changes.

Guidance notes:

Operation of facilities within established parameters and according to legislation is an essential aspect of HS&E and process safety. Management must ensure that the operating manuals and procedures required to support operations are identified, available, accurate, up to date, understood and used.

The commissioning manager must ensure that the necessary operating manuals and procedures are developed for the new plant and equipment in accordance with Guidance on meeting expectations of EI Process safety management framework element 8: Operating manuals and procedures.

In cases where it is a 'brownfield project' which is making modifications to an existing plant, the existing plant operating manuals and procedures should be updated and reissued incorporating the changes which have been made by the project.

Actions

Implement required control measures

As defined in step 09g (02)

As per step 09h (01)

Deliverables

Required control measures implemented:

- in full, and

- in accordance with the schedule defined in step 09h (01).

Frequency

As required by schedule.

Guidance notes:

The commissioning manager should ensure that the agreed required control measures identified in step 09g (02) are implemented in accordance with the plans and schedules agreed in step 09h (01).

The commissioning manager accountable for the implementation of control measures should ensure that their implementation is monitored and managed through to completion and that their effectiveness is assessed and reviewed.

Actions

Ensure personnel are competent in:

- acceptance checking;

- commissioning;

- start-up procedures, and

- plant operation and maintenance

Deliverables

Training material.

Competency assessment training schedule.

Competent persons for:

- acceptance checking;

- commissioning;

- start-up;

- plant operation;

- plant inspection, and

- testing and maintenance.

In accordance with Guidance on meeting expectations of EI Process safety management framework element 3: Employee selection, placement and competency, and health assurance

Frequency

As required by the schedule.

Guidance notes:

The commissioning manager should ensure that all appropriate personnel are aware of, understand and are competent in, the application of the relevant procedures for:

- acceptance checking;

- commissioning;

- plant operation, and

- plant and equipment testing, inspection and maintenance.

Establishing, developing, verifying and maintaining the required competencies should be done in accordance with Guidance on meeting expectations of EI process safety management framework Element 3: Employee selection, placement, competency and health assurance.

Actions

Carry out handover acceptance checking

Review whether handover criteria are met

Agree and implement what is required to meet handover criteria

Deliverables

All plant systems and equipment checked against handover acceptance criteria.

Punch list (outstanding work) items identified and categorised in accordance with criteria defined in step 04.

Agreed plan and schedule to resolve punch list items.

Punch list items resolved in full and in accordance with the agreed schedule.

All plant systems and equipment meet defined criteria for handover to commissioning team.

Frequency

As required by the schedule.

Guidance notes:

On completion of construction the commissioning manager should ensure that the new plant and equipment is systematically checked against the agreed handover criteria, in accordance with the agreed schedule and plans, defined in step 09h (01) and step 09h (02).

Punch list (outstanding work) items should be identified and categorised according to the criteria defined in step 04. Typically the punch list items will be assigned to one of the following categories:

- Category A – Must be completed before handover for commissioning can be approved.

- Category B – Must be completed before project start-up can be approved.

- Category C – Can be completed after plant start-up.

The review should assess whether the handover acceptance criteria have been met for each identified plant system and equipment item. This will require all Category A punch list items to have been completed.

In cases where there are outstanding Category A punch list items, the commissioning team should work with the project construction team to identify and implement what needs to be done in order to complete these outstanding items and meet the handover criteria.

The commissioning team should also work with the project construction team to ensure that there are robust plans and schedules in place to complete the outstanding Category B and C punch list items in the required time frame in accordance with the overall project schedule.

Actions

Review whether plant systems, equipment and personnel are ready to start commissioning

Agree and implement what is required to gain approval

Deliverables

All aspects of preparation for commissioning checked to ensure that they have been completed to a satisfactory standard.

Agreed plan and schedule to resolve remaining punch list items.

Punch list (outstanding work) items cleared in accordance with categorisation criteria defined in step 04.

Commissioning start approved by line manager with the necessary delegated authority.

Frequency

As required by the schedule.

Guidance notes:

When the commissioning team are satisfied that all the handover acceptance criteria have been achieved and that all Category A punch list items have been completed, readiness to initiate commissioning should be reviewed with a line manager with the necessary delegated authority to approve start of commissioning.

This review should also assess other aspects of readiness, including availability of suitable plant commissioning plans and procedures and the availability and competency of the required numbers of personnel for the commissioning activities. These precommissioning activities should have been included in the commissioning plans and schedules developed in step 09d and updated in step 09h. Progress of these items should have been monitored and managed throughout the project’s development and implementation.

The review should also ensure that there are robust plans and schedules in place to complete the outstanding Category B and C punch list items in the required time frame in accordance with the overall project schedule.

In cases where outstanding Category A issues are identified, the required actions to resolve these issues and gain approval to start commissioning should be identified and implemented.

Actions

Carry out commissioning of plant systems and equipment

Deliverables

Commissioning of plant systems and equipment completed:

− in full;

− in accordance with commissioning plans and procedures, and

− in accordance with the commissioning schedule.

Frequency

As required by the schedule, after approval to start commissioning has been granted.

Guidance notes:

Once approval to initiate commissioning has been granted, commissioning should be carried out in accordance with the commissioning plans, procedures and schedules.

The commissioning team should ensure that any issues with the commissioning plans, procedures and schedules are appropriately resolved in accordance with the management of change arrangements and that the issues are recorded as input to the review as defined in step 09i (20).

Actions

Review whether commissioning criteria are met

Agree and implement what is required to meet commissioning criteria

Deliverables

All plant systems and equipment checked against commissioning completion criteria.

Punch list (outstanding work) items identified and categorised in accordance with criteria defined in step 09i (01).

Agreed plan and schedule to resolve punch list items.

Punch list items resolved in full and in accordance with the agreed schedule.

All plant systems and equipment meet defined commissioning completion criteria for commencement of process start-up.

Frequency

As required by the schedule.

Guidance notes:

The commissioning manager or commissioning lead should ensure that the new plant and equipment is systematically checked against the agreed commissioning criteria, in accordance with the agreed schedule and plans, defined in step 09h (03) and step 09h (04).

Punch list (outstanding work) items should be identified and categorised according to the criteria define in step 08. Typically the punch list items identified at this stage will be assigned to one of the following categories:

- Category B – Must be completed before project start-up can be approved.

- Category C – Can be completed after plant start-up.

The review should assess whether the commissioning criteria have been met for each identified plant system and equipment item. This will require all Category B punch list items to have been completed.

In cases where there are outstanding Category B punch list items the commissioning team should work with the project construction team to identify and implement what needs to be done in order to complete these outstanding items and meet the commissioning criteria.

The commissioning team should also work with the project construction team to ensure that there are robust plans and schedules in place to complete the identified Category C punch list items in the required time frame in accordance with the overall project schedule.

Actions

Review whether plant systems, equipment and personnel are ready to commence startup

Agree and implement what is required to gain approval

Deliverables

All aspects of commissioning checked to ensure that they have been completed to a satisfactory standard.

Agreed plan and schedule to resolve remaining punch list items.

Punch list (outstanding work) items cleared in accordance with categorisation criteria defined in step 09i (01).

Commencement of start-up approved by line manager with the necessary delegated authority.

Frequency

As required by the schedule.

Guidance notes:

When the commissioning team are satisfied that all the commissioning criteria have been achieved and that all Category B punch list items have been completed, readiness to commence start-up (bring the plant into operation) should be reviewed with a line manager with the necessary delegated authority to approve commencement of start-up.

This review should also assess other aspects of readiness, including availability of suitable plant start-up plans and procedures and the availability and competency of the required numbers of personnel for the start-up. These pre-commissioning activities should have been included in the commissioning plans and schedules developed in step 9d and updated in step 09h. Progress of these items should have been monitored and managed throughout the project’s development and implementation.

The review should also ensure that there are robust plans and schedules in place to complete the outstanding Category C punch list items in the required time frame in accordance with the overall project schedule.

In cases where outstanding Category B issues are identified, the required actions to resolve these issues and gain approval to commence start-up should be identified and implemented.

Actions

Progress start-up

Deliverables

Plant start-up carried out in accordance with start-up procedure defined in step 09i (06).

Issues and opportunities for improvements to start-up procedure identified.

Frequency

As required by the schedule, after approval for start-up has been granted.

Guidance notes:

Once approval to commence start-up has been granted, the start-up should be carried out in accordance with the start-up plans and procedures defined in step 09i (6) and step 09h.

The commissioning and start-up team should ensure that any issues with the start-up plans and procedures are appropriately resolved in accordance with the management of change arrangements and that the issues are recorded as input to the review as defined in step 09i (20).

Actions

Review commissioning and start-up

Update:

- plant documentation and records;

- operating manual;

- operating procedures;

- maintenance manual, and

- standards and practices

Deliverables

Systematic review of all aspects of the commissioning and start-up, identifying:

- what went well;

- issues which need to be addressed, and

- opportunities for improvements.

Updated:

- plant documentation and records;

- operating manual;

- operating procedures;

- maintenance manual, and

- standards and practices

Frequency

Soon after startup.

Guidance notes:

The commissioning manager should ensure that there is formal systematic review of the commissioning and start-up. Ideally this should take place soon after the start-up has been completed and the plant has achieved a lined out, stable operation. The review should take input from all participants in the commissioning and start-up activities and should identify:

- what went well;

- issues which need to be addressed, and

- opportunities for improvement.

The identified issues and opportunities should be ranked and prioritised and the commissioning manager should ensure that appropriately resourced plans are established to progress these items. Typically these items will involve updating of:

- plant documentation and records;

- operating manuals;

- operating procedures;

- maintenance manuals, and

- standards and practices.

There will be occasions where the issue or opportunity would need to be addressed by means of another (minor) project. In these cases the item should be screened and ranked and progressed appropriately considering its prioritisation in accordance with Guidance on meeting expectations of EI Process safety management framework element 12: Management of change and project management.

Actions

Review plant performance

Review whether design basis has been achieved and suitability for handover to operations team

Agree plan and resolve issues

Deliverables

Performance of all plant systems and equipment checked against design basis.

Punch list (outstanding issues and work) items identified and categorised in accordance with criteria defined in step 09i (01).

Agreed plan and schedule to resolve punch list items.

Punch list items resolved in full and in accordance with the agreed schedule.

Handover to operations team accepted and approved by line manager with the necessary delegated authority.

Frequency

As required by the schedule.

Guidance notes:

Following a period of lined out stable operation, the commissioning manager should ensure that a performance test is carried out to evaluate the performance of all plant systems and equipment and assess whether they are capable of meeting the design basis.

In cases where issues are identified they should be screened and ranked and prioritised and a decision made as to how they will be progressed. A key issue to consider at this stage is who will have accountability for resolution of any identified issues and whether they will stop handover of the new project to the operations (owner) team.

The commissioning manager should work with the receiving line manager to ensure that there is a robust resourced plan and schedule in place to resolve any identified issues and any outstanding Category C punch list items. They should also agree which of these items, if any, must be completed as a pre-condition for handover of the new project to the operations (owner) team.

Handover of the new project to the operations (owner) team should be reviewed and approved by a line manager with the necessary delegated authority.

Actions

Handover to operations team

Review plant commissioning and start-up.

Deliverables

Handover to operations team:

- plant;

- manuals and procedures;

- documentation and records, and

- agreed plan to resolve any outstanding issues and work items.

Demobilisation of commissioning and start-up team.

Frequency

After approval to handover to operations team has been granted.

Guidance notes:

Following approval to handover the new project to the operations (owner) team, the commissioning manager and the receiving line manager must ensure that all necessary information is transferred into the custody of the appropriate person in the 'business as usual' situation. This will include:

- manuals and procedures;

- documentation and records;

- agreed plans to resolve outstanding issues, and

- agreed budgets to fund resolution of outstanding issues.

The commissioning team can be demobilised after handover, in accordance with the commissioning plan.

Actions

Review project impact on business performance

Review whether project basis has been achieved and whether the project can be closed out.

Agree plan and resolve issues.

Deliverables

Systematic review of impact of the project on overall business performance checked against project basis, identifying:

- what went well;

- issues which need to be addressed before close out of this project;

- issues which need to be addressed for future projects.

Agreed plan to resolve outstanding issues.

Close out of project approved by line manager with the necessary delegated authority.

Frequency

As required by the schedule.

After approval to close out project has been granted.

Guidance notes:

Following a sustained period of lined out stable operation, typically between six months and a year, it is advisable to review the overall performance of the project and assess whether it is achieving the business benefits that provided the initial justification for the project in the project basis, and the approved investment business case. The commissioning manager should ensure that accountability for this review is assigned at the time of handover to the operation (owner) team.

Any identified issues that need to be resolved should be ranked, screened and prioritised and progressed appropriately.

The final close out of the project should be reviewed and approved by a line manager with the necessary delegated authority.

Actions

Identify potential partial or full plant trip or shutdown scenarios

Deliverables

Agreed listing of possible full or partial plant trip scenarios.

Agreed listing of possible full or partial plant shutdown scenarios.

Frequency

During implementation then updated as required (review after each trip or shutdown).

Guidance notes:

The element owner should ensure that potential partial or full plant trip or shutdown scenarios are identified. A listing of plant ESD systems will provide a good starting point for this work as it will identify all plant systems and equipment which have automated trip systems.

Actions

Identify potential hazards

Risk assess identified hazards and identify required control measures.

Develop plans to implement required control measures.

Deliverables

Agreed listing of identified potential hazards arising from or during restart after each identified trip or shutdown scenario.

Completed risk assessments of identified potential hazards.

Required status checks and control measures.

Frequency

During implementation, then updated as required (review after each trip or shutdown).

Guidance notes:

The element owner should ensure that a review is carried out to identify potential hazards arising from the trip and shutdown scenarios. These identified hazards should be risk assessed and the required post trip plant status checks and control measures identified. The hierarchy of control should be applied when selecting the risk control measures:

- elimination;

- reduction;

- interception;

- control;

- personal protective equipment (PPE);

- discipline (making sure that all controls are monitored reviewed and enforced), and

- emergency response.

These status checks and risk control measures will provide a major input to the development of the restart procedures for each scenario.

The completed risk assessments for should be reviewed and approved by an appropriate line manager with the necessary competency and delegated level of authority.

Actions

Develop restart procedures

Deliverables

Approved plant restart procedures for each identified trip and shutdown scenario, in accordance with Guidance on meeting expectations of EI Process safety management framework element 8: Operating manuals and procedures, setting out the necessary information and procedures to support:

- safe start-up;

- actions to be taken in event of excursions beyond defined operating limits;

- actions to be taken in response to alarm or trip conditions, and

- safe shutdown.

Training of personnel.

Frequency

During implementation, then updated as required.

Guidance notes:

The element owner should ensure that the necessary restart procedures are developed for each identified trip or shutdown scenario, in accordance with Guidance on meeting expectations of EI Process safety management framework element 8: Operating manuals and procedures.

The restart procedures should incorporate the post trip status checks and control measures identified in step 10c.

Actions

Ensure personnel are competent in restart procedures

Deliverables

Training material.

Competency assessment.

Training schedule.

Competent persons for restart for each of the identified trip or shutdown scenarios. In accordance with Guidance on meeting expectations of EI process safety management framework Element 3: Employee selection, placement and competency, and health assurance.

Frequency

During implementation, then updated to maintain required competency levels.

Guidance notes:

The element owner should ensure that all appropriate personnel are aware of, understand and are competent in, the application of the all of the re-start procedures. This should be a core competency for plant operations personnel, as they may be required to implement these procedures at any time following a trip situation.

Establishing, developing, verifying and maintaining the required competencies should be done in accordance with Guidance on meeting expectations of EI process safety management framework Element 3: Employee selection, placement and competency, and health assurance.

Actions

Carry out required status checks and implement required control measures

Identify and prioritise required actions to establish stable plant conditions

Deliverables

Control measures identified in step 10c implemented in full.

Systematic plant status checks carried out as defined in step 10c.

Clear understanding of plant status.

Prioritised listing of identified issues which need to be resolved in order to establish stable plant conditions.

Frequency

After trip or shutdown.

Guidance notes:

Following a trip situation, the plant operations supervisor should identify the trip scenario and ensure that the required plant status checks and immediate control measures are carried out.

Utilising the feedback from the plant status checks, the plant operations supervisor should work with the operations team to identify and prioritise the actions required to establish stable plant conditions.

Actions

Implement identified actions

Review whether stable plant conditions have been established

Consider shutdown if stable conditions cannot be established

Deliverables

Actions identified in step 10g implemented.

Systematic review of plant status.

Decision to continue or decision to consider plant shutdown approved by a line manager with the necessary delegated authority.

Frequency

After trip or shutdown.

Guidance notes:

The plant operations supervisor should ensure that the prioritised actions to establish stable plant conditions, identified in step 10g, are implemented by the operations team.

The plant operations supervisor should continually monitor the situation and if it is not possible to establish stable plant conditions within a reasonable period of time, the plant operations supervisor should consider shutting down the plant so that a restart can be initiated from a known situation.

Actions

Check for suitable restart procedure

Hold plant in stable condition or consider shutdown if suitable procedure is not available

Deliverables

Review of available restart procedures by authorised competent person.

Decision to continue with restart if suitable procedure is available.

Decision to hold or consider shutdown if suitable procedure Is not available.

Decision made by line manager with the necessary delegated authority.

Frequency

Before restart.

Guidance notes:

The plant operations supervisor should check that there is a suitable procedure available for restart from the current trip scenario with the current plant conditions.

If there is no suitable re-start procedure available, the plant operations supervisor should consider whether the plant can be held in the current stable condition whilst a suitable procedure is sourced or whether the plant should be shut down so that a restart can be initiated from a known situation.

Actions

Review whether plant and personnel are ready for restart

If plant restart is not approved hold plant in stable condition or consider shutdown

Agree and implement what is required to gain approval for restart

Deliverables

All aspects of preparation for restart checked to ensure that they have been completed to a satisfactory standard.

Agreed plan and schedule to resolve remaining punch list items.

Punch list (outstanding work) items cleared.

Decision to hold plant in stable condition or shutdown if restart is not approved.

Restart approved by line manager with the necessary delegated authority.

Frequency

Before restart.

Guidance notes:

When the plant operations supervisor is satisfied that the plant is in a stable condition and that a suitable re-start procedure is available, readiness to commence restart (bring the plant back into operation) should be reviewed with a line manager with the necessary delegated authority to approve commencement of re-start.

This review should also assess other aspects of readiness, including the availability and competency of the required numbers of personnel for the restart.

If the restart is not approved the required actions to gain approval to restart should be identified and implemented. In this case a decision should be made as to whether the plant will be held in the current stable condition or whether it should be fully shut down whilst the required actions are carried out.

Actions

Progress with restart

Deliverables

Plant restart carried out in accordance with restart procedure defined in step 10d.

Frequency

After approval to restart has been granted.

Guidance notes:

Once approval to commence restart has been granted, the start-up should be carried out in accordance with the appropriate start-up procedure defined in step 10d.

The plant operations supervisor should ensure that any issues with the restart procedures are appropriately resolved in accordance with the management of change arrangements and that the issues are recorded as input to the review as defined in step 10p.

Actions

Review restart

Deliverables

Systematic review of all aspects of the restart, identifying:

- what went well;

- issues which need to be addressed, and

- opportunities for improvements.

Updated:

- operating manual, and

- restart procedures.

Frequency

Soon after restart.

Guidance notes:

The plant operations supervisor should ensure that there is formal systematic review of the restart. Ideally this should take place soon after the restart has been completed and the plant has achieved a lined out, stable operation. The review should take input from all participants in the restart activities and should identify:

- what went well;

- issues which need to be addressed, and

- opportunities for improvement.

The identified issues and opportunities should be ranked and prioritised and the plant operations supervisor should ensure that appropriately resourced plans are established to progress these items.

Typically these items will involve updating of:

- plant documentation and records;

- operating manuals, and

- operating procedures.

There will be occasions where the issue or opportunity would need to be addressed by means of a maintenance work item or a (minor) project. In these cases the item should be screened and ranked and progressed appropriately considering its prioritisation in accordance with Guidance on meeting expectations of EI Process safety management framework element 15: Inspection and maintenance or Guidance on meeting expectations of EI Process safety management framework element 12: Management of change and project management

Actions

Define maintenance, inspection and testing work scope

Deliverables

Maintenance, inspection and testing work scope defined in accordance with Guidance on meeting expectations of EI Process safety management framework element 15: Inspection and maintenance and Guidance on meeting expectations of EI Process safety management framework element 16: Management of safety critical devices.

Frequency

As required by schedule.

Actions

Identify equipment impacted by work scope

Deliverables

Listing of plant systems and equipment which will be included in the work scope or impacted by the work scope.

Frequency

As required by schedule.

Guidance notes:

Planning for re-start after maintenance should start as early as possible, ideally as soon as the plant shutdown wordlist has been defined.

The work list should be defined in accordance with Guidance on meeting expectations of EI Process safety management framework element 15: Inspection and maintenance and Guidance on meeting expectations of EI Process safety management framework element 16: Management of safety critical devices.

When the work list is available an assessment should be carried out to identify the plant systems and equipment which will be impacted by the proposed work scope. Additionally the equipment preparation plans and procedures should be reviewed. This will provide a clear picture of what work will be carried out on each plant system and the conditions that will have been created in each of the plant systems during process preparation, flushing and degassing.

Actions

Identify potential restart hazards

Deliverables

Identified potential restart hazards

Frequency

As required by schedule

Actions

Risk assess identified hazards and identify required control measures, equipment status and recommissioning checks

Deliverables

Completed risk assessments of identified potential restart hazards.

Required control measures

Equipment status checks

Recommissioning checks

Frequency

As required by schedule

Guidance notes:

The nominated restart leader should ensure that, a review is carried out to identify potential hazards arising from the recommissioning and restart of the plant taking into account the work scope and the plant systems and equipment impacted by the work scope. These identified hazards should be risk assessed and the required control measures identified. The hierarchy of control should be applied when selecting the risk control measure:

- elimination;

- reduction;

- interception;

- control;

- personal protective equipment (PPE);

- discipline (making sure that all controls are monitored reviewed and enforced), and

- emergency response.

The re-start leader should ensure that appropriate feasible plans and schedules should be developed for the implementation of the agreed required control measures.

The completed risk assessments for should be reviewed and approved by an appropriate line manager with the necessary competency and delegated level of authority.

Actions

Define and agree handback criteria for handover from maintenance

Develop handback acceptance checking plans

Develop handback acceptance checking schedule

Deliverables

Agreed acceptance criteria for handback of equipment from maintenance to recommissioning and startup team.

Agreed handback acceptance checking plans and schedule, setting out:

- how acceptance checking will be carried out;

- who will carry-out the acceptance checking;

- who will have authority to accept handover of equipment to the recommissioning and startup team, and

- when acceptance checking will be carried out.

Frequency

As required by schedule.

Guidance notes:

Criteria for accepting handover of plant systems and equipment should be agreed between the maintenance team leader and the restart leader. These should take account of predefined criteria as defined in step 08. These may need to be updated as the level of definition of the work scope increases as the maintenance planning progresses.

A plan and schedule should be developed for the handover acceptance checking. Plans and schedules should be developed for each system and they should be developed in conjunction with the maintenance plan and schedule. The appropriate integration and optimisation of these plans and schedules may provide opportunities to shorten the overall schedule and advance the date when the plant is brought back online, with the consequent reduced shutdown duration and reduction in lost production.

Actions

Develop recommissioning procedures and completion criteria

Develop recommissioning plans

Develop recommissioning schedule

Deliverables

Agreed recommissioning procedures with agreed criteria for progression from recommissioning to start-up.

Agreed recommissioning plans and schedule, setting out:

- how recommissioning will be carried out;

- where recommissioning will be carried out;

- the resource required and who will carry out the recommissioning;

- who will have authority to approve progression from re-commissioning to startup, and

- when recommissioning will be carried out.

Frequency

As required by schedule.

Guidance notes:

Re-commissioning procedures should be developed and criteria for progressing from re-commissioning to start-up should be reviewed and approved by a line manager with the necessary delegated authority. These should take account of predefined re-commissioning safe working practices as defined in step 06 and any predefined acceptance criteria as defined in step 08. These may need to be updated as the level of definition of the work scope increases as the maintenance planning progresses.

A plan and schedule should be developed for the recommissioning. Plans and schedules should be developed for each system and they should be developed in conjunction with the maintenance plan and schedule and handback acceptance checking schedule. The appropriate integration and optimisation of these plans and schedules may provide opportunities to shorten the overall schedule and advance the date when the plant is brought back online, with the consequent reduced shutdown duration and reduction in lost production.

Actions

Implement required control measures

As defined in step 11d.

Deliverables

Required control measures implemented:

- in full, and

- on time.

Frequency

As required by schedule.

Guidance notes:

The restart leader should ensure that the agreed required control measures identified in step 11d are implemented in accordance with the agreed plans and schedules.

The restart leader accountable for the implementation of control measures should ensure that their implementation is monitored and managed through to completion and that their effectiveness is assessed and reviewed.

Actions

Develop plant startup procedure

This should be reviewed and approved by persons with the delegated authority to do so.

Deliverables

Approved plant start-up procedure, in accordance with Guidance on meeting expectations of EI Process safety management framework element 8: Operating manuals and procedures, setting out the necessary information and procedures to support:

- safe start-up;

- actions to be taken in event of excursions beyond defined operating limits;

- actions to be taken in response to alarm or trip conditions.;

- safe shutdown, and

- training of personnel.

Frequency

As required by the schedule.

Guidance notes:

The re-start leader must ensure that the necessary start-up procedures are developed in accordance with Guidance on meeting expectations of EI Process safety management framework element 8: Operating manuals and procedures.

Actions

Ensure personnel are competent in acceptance checking, re-commissioning and start-up procedures

Deliverables

Training material.

Competency assessment.

Training schedule.

Competent persons for:

- acceptance checking;

- recommissioning, and

- start-up.

In accordance with Guidance on meeting expectations of EI Process safety management framework Element 3: Employee selection, placement and competency, and health assurance.

Frequency

As required by the schedule.

Guidance notes:

The restart leader should ensure that all appropriate personnel are aware of, understand and are competent in, the application of the relevant procedures for:

- acceptance checking;

- recommissioning;

- plant start-up.

Establishing, developing, verifying and maintaining the required competencies should be done in accordance with Guidance on meeting expectations of EI Process safety management framework Element 3: Employee selection, placement and competency, and health assurance.

Actions

Carry out handback acceptance checking

Review whether handback criteria are met.

Agree and implement what is required to meet handback criteria.

Deliverables

All plant systems and equipment checked against handback acceptance criteria.

Punch list (outstanding work) items identified and categorised in accordance with criteria defined in step 09i (01).

Agreed plan and schedule to resolve punch list items.

Punch list items resolved in full and in accordance with the agreed schedule.

All plant systems and equipment meet defined criteria for handback to recommissioning team.

Frequency

As required by the schedule.

Guidance notes:

On completion of the maintenance work scope the re-start leader should ensure that the plant systems and equipment are systematically checked against the agreed handover criteria, in accordance with the agreed schedule and plans, defined in step 11e, step 11f and step 11g.

Punch list (outstanding work) items should be identified and categorised according to the criteria defined in step 08. Typically the punch list items will be assigned to one of the following categories:

- Category A – Must be completed before handover for recommissioning can be approved.

- Category B – Must be completed before completed before plant restart can be approved.

- Category C – Can be completed after plant restart.

The review should assess whether the handback acceptance criteria have been met for each identified plant system and equipment item. This will require all Category A punch list items to have been completed.

In cases where there are outstanding Category A punch list items the restart leader should work with the maintenance team leader to identify and implement what needs to be done in order to complete these outstanding items and meet the handback criteria.

The re-start leader team should also work with the maintenance team leader to ensure that there are robust plans and schedules in place to complete the outstanding Category B and C punch list items in the required time frame in accordance with the overall shutdown schedule.

Actions

Review whether plant systems, equipment and personnel are ready to start recommissioning

Agree and implement what is required to gain approval

Deliverables

All aspects of preparation for re-commissioning checked to ensure that they have been completed to a satisfactory standard.

Agreed plan and schedule to resolve remaining punch list items.

Punch list (outstanding work) items cleared in accordance with categorisation criteria defined in step 09i (01).

Re-commissioning start approved by line manager with the necessary delegated authority.

Frequency

As required by the schedule.

Guidance notes: